DMCH Lower ball joints IS THIS WHY THEY FAIL??????

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

Yes that's correct. VX220 and Elise have a lot of common chassis components as they are very similar under the bodywork.

- Phil349

- Posts: 86

- Joined: Tue Jul 07, 2009 11:36 pm

- VIN #: 1128

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

The VX220 was Lotus's way of getting somebody to pay for the development of the S2 Elise.

The VX220 is almost the same as the S2 elise but lotus used Vauxhalls money to develop the the VX and then based the S2 on all of its development.

The Ball joints are from a Vauxhall Chevette

The VX220 is almost the same as the S2 elise but lotus used Vauxhalls money to develop the the VX and then based the S2 on all of its development.

The Ball joints are from a Vauxhall Chevette

Dan Shane

DCUK 008

Ex VIN 4754

The Black Stig

DeLorean Club

The Future's Bright....

The Future's DeLorean Club

DCUK 008

Ex VIN 4754

The Black Stig

DeLorean Club

The Future's Bright....

The Future's DeLorean Club

-

Daniel Shane - Posts: 461

- Joined: Fri Jun 05, 2009 1:29 pm

- VIN #: Ex 4754

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

Ok,

I got the modified VW joint in the mail today. Many Thanks Phil.

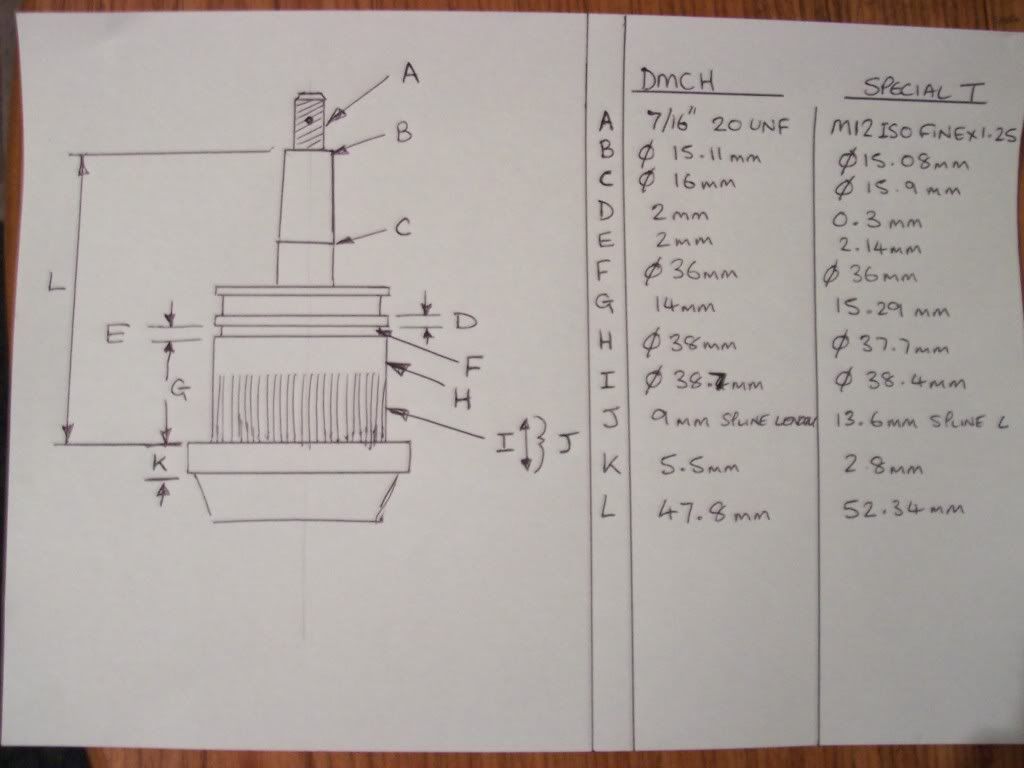

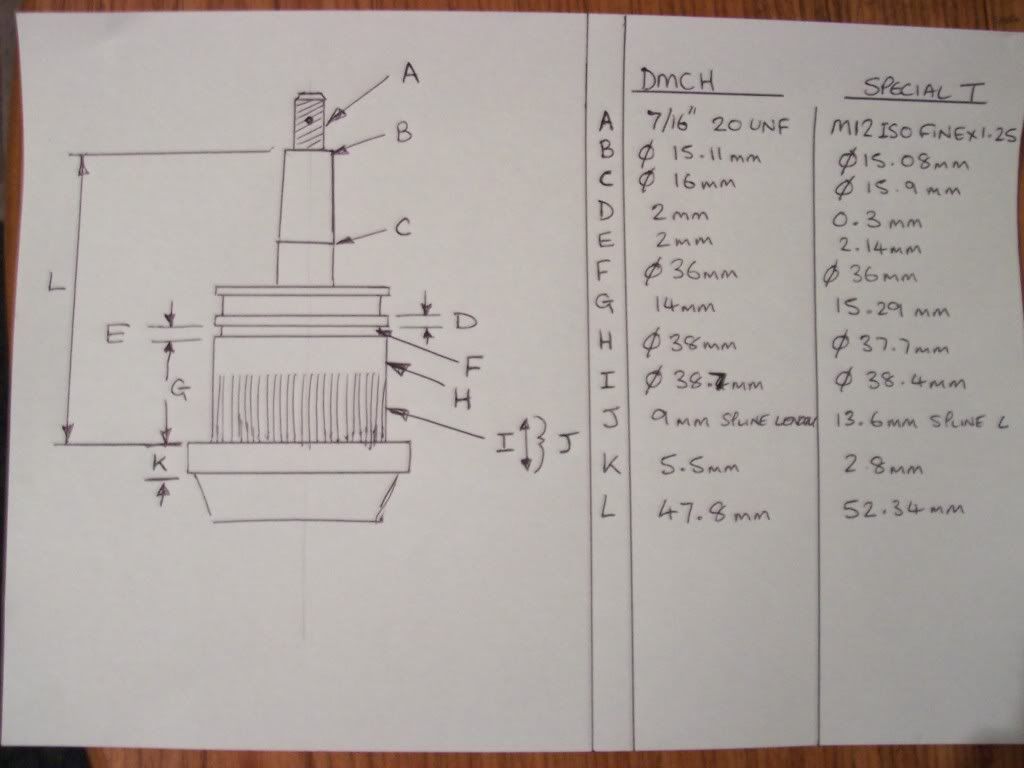

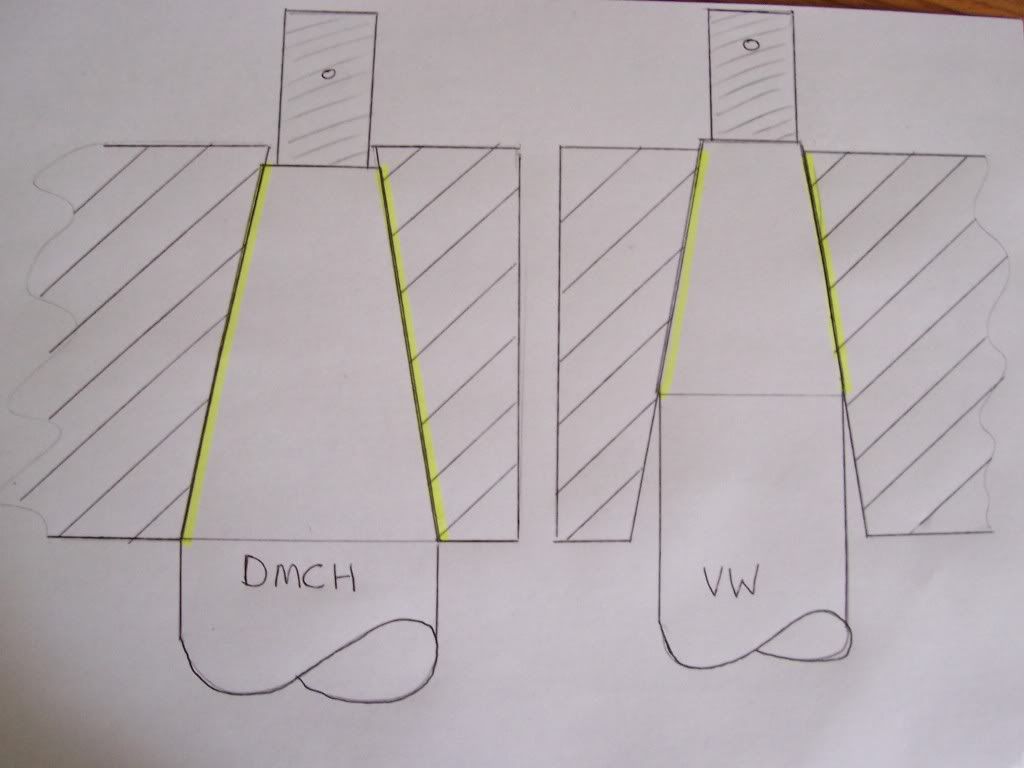

Here’s a comparison with the DMCH joint made to DMC dimensions. I would definitely NOT fit this modified VW joint due to the poor quality of the re-work machining. We knew this already, and this is why the club has stopped stocking them, but I thought it would be of interest to the community to understand why.

Basically if you take a look at the comparison chart size D is very worrying. Only 0.3mm of metal is stopping the circlip poping upwards and the joint falling down in the lower arm. If anyone has fitted these to their car I strongly advise against driving it.

Incidentally if you take a look at size G you’ll note that whoever modified these joints cut the circlip recess 1.29mm too high which resulted in a 0.3mm shoulder instead of at least 1.59mm that would have been available.

I can also confirm despite previous posts the taper on the shaft of these joints is THE SAME as the DMCH joint. However I should point out size L, the VW joint has a longer shaft, but if you measure the DMCH at the top of the taper (size B) then the VW at a point 4mm down (size B again) you get a similar size. Then if you measure point C (10mm down from where you measure B on both) you also get a similar size. Therefore in relation to where the taper shaft sits in the hub (despite the VW being longer) they are pretty much identical. Again there is a caveat, The VW shaft will extend further through the Hub as it is longer which may mean when the nut reaches the bottom of its thread it could possibly not lock the tapers together. This could be resolved by fitting a washer under the nut if this situation occurs.

Another point of note is that the VW taper stops short (it passes 10mm down the shaft from the thread) then the shaft becomes parallel. This has the optical effect of making you think the two tapers are not the same, and if you measure the bottoms of each shaft the VW is smaller due to the DMCH joint continuing its taper by a further 5mm down the shaft. Now then…this means the shaft is a lot thinner at the top of the ball on the VW compared to the DMCH, which will mean its weaker at this point. Additionally the reduced taper length from 15mm down to 10mm means less contact between tapers on joint and hub. Again this would mean less force is required to break the taper lock.

Looking at the spline, although shorter on the DMCH joint than the VW, I can see no problems here with a good match.

Size K is smaller on the VW, but to be fair there is still more than enough material to prove strong enough for the task.

Interestingly the VW has a better thread form and size, albeit an ISO fine, which will mean a specialist stockist to obtain a castle nut, or careful modification of the supplied nut.

In summary:

If you have one of these ball joints fitted to your car and the circlip is as badly positioned/machined as in the one I’ve been sent, then I’d advise against driving the car, and to get it replaced ASAP.

If you have one that’s had the circlip grove cut at 14mm up from the shoulder leaving at least 1.5mm of shoulder above the circlip, you should be fine (providing the nut hasn’t bottomed out before the taper has locked).

As I reported earlier, with the lower arm under spring tension you wont feel the play, but this could cause possible movement which in turn could lead to the shaft of the joint necking or even shearing off. (This failure is not uncommon, and I’d place bets that’s what’s happened)

Also be aware that your taper contact and shaft are reduced too with the VW joint.

I’ve ordered a Lotus/Vauxhall joint and will do a further analysis of suitability when it arrives, in my quest to find the “best” alternative joint until DMCH resolve their failure record.

It's absolutely criminal that this badly modified joint entered the market, there is enough evidence to hang the supplier

I got the modified VW joint in the mail today. Many Thanks Phil.

Here’s a comparison with the DMCH joint made to DMC dimensions. I would definitely NOT fit this modified VW joint due to the poor quality of the re-work machining. We knew this already, and this is why the club has stopped stocking them, but I thought it would be of interest to the community to understand why.

Basically if you take a look at the comparison chart size D is very worrying. Only 0.3mm of metal is stopping the circlip poping upwards and the joint falling down in the lower arm. If anyone has fitted these to their car I strongly advise against driving it.

Incidentally if you take a look at size G you’ll note that whoever modified these joints cut the circlip recess 1.29mm too high which resulted in a 0.3mm shoulder instead of at least 1.59mm that would have been available.

I can also confirm despite previous posts the taper on the shaft of these joints is THE SAME as the DMCH joint. However I should point out size L, the VW joint has a longer shaft, but if you measure the DMCH at the top of the taper (size B) then the VW at a point 4mm down (size B again) you get a similar size. Then if you measure point C (10mm down from where you measure B on both) you also get a similar size. Therefore in relation to where the taper shaft sits in the hub (despite the VW being longer) they are pretty much identical. Again there is a caveat, The VW shaft will extend further through the Hub as it is longer which may mean when the nut reaches the bottom of its thread it could possibly not lock the tapers together. This could be resolved by fitting a washer under the nut if this situation occurs.

Another point of note is that the VW taper stops short (it passes 10mm down the shaft from the thread) then the shaft becomes parallel. This has the optical effect of making you think the two tapers are not the same, and if you measure the bottoms of each shaft the VW is smaller due to the DMCH joint continuing its taper by a further 5mm down the shaft. Now then…this means the shaft is a lot thinner at the top of the ball on the VW compared to the DMCH, which will mean its weaker at this point. Additionally the reduced taper length from 15mm down to 10mm means less contact between tapers on joint and hub. Again this would mean less force is required to break the taper lock.

Looking at the spline, although shorter on the DMCH joint than the VW, I can see no problems here with a good match.

Size K is smaller on the VW, but to be fair there is still more than enough material to prove strong enough for the task.

Interestingly the VW has a better thread form and size, albeit an ISO fine, which will mean a specialist stockist to obtain a castle nut, or careful modification of the supplied nut.

In summary:

If you have one of these ball joints fitted to your car and the circlip is as badly positioned/machined as in the one I’ve been sent, then I’d advise against driving the car, and to get it replaced ASAP.

If you have one that’s had the circlip grove cut at 14mm up from the shoulder leaving at least 1.5mm of shoulder above the circlip, you should be fine (providing the nut hasn’t bottomed out before the taper has locked).

As I reported earlier, with the lower arm under spring tension you wont feel the play, but this could cause possible movement which in turn could lead to the shaft of the joint necking or even shearing off. (This failure is not uncommon, and I’d place bets that’s what’s happened)

Also be aware that your taper contact and shaft are reduced too with the VW joint.

I’ve ordered a Lotus/Vauxhall joint and will do a further analysis of suitability when it arrives, in my quest to find the “best” alternative joint until DMCH resolve their failure record.

It's absolutely criminal that this badly modified joint entered the market, there is enough evidence to hang the supplier

@classiccarguru1

- Darren C

- Posts: 1162

- Joined: Wed Jul 22, 2009 8:55 pm

- Location: In the garage, Emsworth. Hants

- VIN #: 4532

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

That makes for very interesting reading Darren. I'm looking forward to reading your analysis on the Lotus balljoint.

One thing though, although that circlip is there to stop the ball joint dropping in the arm, with the car on its wheels the balljoint is being pulled up into the arm so the chances of the joint actually dropping in the arm are very slim I would think ? I can see its certainly not ideal though!!!

One thing though, although that circlip is there to stop the ball joint dropping in the arm, with the car on its wheels the balljoint is being pulled up into the arm so the chances of the joint actually dropping in the arm are very slim I would think ? I can see its certainly not ideal though!!!

Sell it Or Sorn it

Road trips:

2008: Mervyn's Delorean Weekend, Ireland

2008: DMC Europe Open House

2009: DMC Europe Open House

2009: Royal Delorean Weekend, Ireland

2010: Silvercoast, France

2010: Shanefest, Ireland

2010: Luxemburg & Nurburgring

2011: Eurofest, Belfast

2019: International DeLorean Meeting, Hamburg

Road trips:

2008: Mervyn's Delorean Weekend, Ireland

2008: DMC Europe Open House

2009: DMC Europe Open House

2009: Royal Delorean Weekend, Ireland

2010: Silvercoast, France

2010: Shanefest, Ireland

2010: Luxemburg & Nurburgring

2011: Eurofest, Belfast

2019: International DeLorean Meeting, Hamburg

-

Dan 6511 - Posts: 3538

- Joined: Fri Jun 05, 2009 5:10 pm

- Location: Essex

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

Nice post Darren. Although I really think you need to test fit the Special T joint in the tapered hole on the steering knuckle, it definately is not the correct tapered fit. Or it wasnt on my car anyway.

I did a lot of the same measurements youve done a while ago, but bear in mind the distance between point B and bottom of the used area of the taper is much shorter on the DMC joint than on the Special T joint, and the special T joints taper does not go to a large enough diameter.

On the other special t joint I have here point B measures 14.63mm (OEM DMC joint is 15.00mm), point c measures 16.12 at which point at which the shaft goes paralell straight down (OEM DMC joint is 17.00mm at the bottom of the taper).

However the issue is that on the OEM DMC joint the taper is used down to about the 16.6mm diameter mark (if I remember correctly - measure the bottom of the tapered hole in the steering knuckle), the special T joint's taper doesnt even go that large, therefore when its fitted in the hole the bottom part of the taper does not make contact with the taper in the hole. Try it. The top part of the taper is the same diameter between both joints and makes contact inside the hole when fitted, the bottom part of the taper does not. The special T joints' tapered shaft does not extend down to a diameter large enough to match up with the hole in the steering knuckle, it stops at 16.1mm diameter. Meaning a loose fit.

It will be held in place with the nut only.

Point B to C is over a distance of 15mm on the special T joint. Point B to point C on the DMC joint is over a distance of 17.5mm, although as said this is slightly irrelevant for the fit as the taper continues to enlarge further down past the point where its used.

However, again on the DMC joint, point B to the point where the shaft diameter measures 16.1mm (which matches point C of the special T joint, which as said is too small) is over a distance of Approx. 10mm. Compared to the special T's 15mm.

The Angle of this used section of the taper is different between the two joints, because the distance between the points where the diameter matches is different.

You say you can measure point B 4mm down from the top of the taper on the special T joint, which makes B 15mm. OK. Same as the DMC joint point B. And 10mm below there both joints have a diameter of 16mm, but, thats where the taper finishes for the special T joint, the DMC one continues on and is used as I say.

Its also worth noting that although the cir clip groove is hardly even machined in at all (its about 0.5mm deep!) and its on the verge of breaking through flush with the top of the casing, so serves no purpose at all as the cir clip would simply slip off. The suspension is trying to pull up on the ball joint, not push it down. Therefore is wont fall out when in use.

It should be right though so its not acceptable. I am more concerned over the taper lock.

I did a lot of the same measurements youve done a while ago, but bear in mind the distance between point B and bottom of the used area of the taper is much shorter on the DMC joint than on the Special T joint, and the special T joints taper does not go to a large enough diameter.

On the other special t joint I have here point B measures 14.63mm (OEM DMC joint is 15.00mm), point c measures 16.12 at which point at which the shaft goes paralell straight down (OEM DMC joint is 17.00mm at the bottom of the taper).

However the issue is that on the OEM DMC joint the taper is used down to about the 16.6mm diameter mark (if I remember correctly - measure the bottom of the tapered hole in the steering knuckle), the special T joint's taper doesnt even go that large, therefore when its fitted in the hole the bottom part of the taper does not make contact with the taper in the hole. Try it. The top part of the taper is the same diameter between both joints and makes contact inside the hole when fitted, the bottom part of the taper does not. The special T joints' tapered shaft does not extend down to a diameter large enough to match up with the hole in the steering knuckle, it stops at 16.1mm diameter. Meaning a loose fit.

It will be held in place with the nut only.

Point B to C is over a distance of 15mm on the special T joint. Point B to point C on the DMC joint is over a distance of 17.5mm, although as said this is slightly irrelevant for the fit as the taper continues to enlarge further down past the point where its used.

However, again on the DMC joint, point B to the point where the shaft diameter measures 16.1mm (which matches point C of the special T joint, which as said is too small) is over a distance of Approx. 10mm. Compared to the special T's 15mm.

The Angle of this used section of the taper is different between the two joints, because the distance between the points where the diameter matches is different.

You say you can measure point B 4mm down from the top of the taper on the special T joint, which makes B 15mm. OK. Same as the DMC joint point B. And 10mm below there both joints have a diameter of 16mm, but, thats where the taper finishes for the special T joint, the DMC one continues on and is used as I say.

Its also worth noting that although the cir clip groove is hardly even machined in at all (its about 0.5mm deep!) and its on the verge of breaking through flush with the top of the casing, so serves no purpose at all as the cir clip would simply slip off. The suspension is trying to pull up on the ball joint, not push it down. Therefore is wont fall out when in use.

It should be right though so its not acceptable. I am more concerned over the taper lock.

- Phil349

- Posts: 86

- Joined: Tue Jul 07, 2009 11:36 pm

- VIN #: 1128

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

I can see what you mean if you take point B as 4mm below the top of the taper (which I did not do to start with above, as I said B is 14.6 on the special t joint as measured, 4mm lower means its 15mm as you say), then B is the same.

And the distance from there to a diameter of 16 is not quite the same but it is close. But I still think its not right as you only have a short taper lock contact area of about 10mm with the special t joint compared to the dmc one, and im not convinced the angle match is exact enough either. You would not be using all of the taper that is available in the hole in the steering knuckle as was designed, which means it feels loose and surely is not as strong as the dmc joints lock would be.

Its good to talk about all this in a forum, its really helpful to be able think aloud and discuss like this!!

And the distance from there to a diameter of 16 is not quite the same but it is close. But I still think its not right as you only have a short taper lock contact area of about 10mm with the special t joint compared to the dmc one, and im not convinced the angle match is exact enough either. You would not be using all of the taper that is available in the hole in the steering knuckle as was designed, which means it feels loose and surely is not as strong as the dmc joints lock would be.

Its good to talk about all this in a forum, its really helpful to be able think aloud and discuss like this!!

- Phil349

- Posts: 86

- Joined: Tue Jul 07, 2009 11:36 pm

- VIN #: 1128

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

That Special T ball joint picture doesnt look the same as the ones I sent to Julian

Jules can you post a picture up of those ??

The groove for the circlip is totally different for starts ...

There has to be an X ref for these, surely can't be unique to D's ...

Jules can you post a picture up of those ??

The groove for the circlip is totally different for starts ...

There has to be an X ref for these, surely can't be unique to D's ...

- bozzzydmc

- Posts: 4402

- Joined: Fri May 29, 2009 8:30 am

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

Phil349 wrote:I can see what you mean if you take point B as 4mm below the top of the taper (which I did not do to start with above, as I said B is 14.6 on the special t joint as measured, 4mm lower means its 15mm as you say), then B is the same.

And the distance from there to a diameter of 16 is not quite the same but it is close. But I still think its not right as you only have a short taper lock contact area of about 10mm with the special t joint compared to the dmc one, and im not convinced the angle match is exact enough either. You would not be using all of the taper that is available in the hole in the steering knuckle as was designed, which means it feels loose and surely is not as strong as the dmc joints lock would be.

Its good to talk about all this in a forum, its really helpful to be able think aloud and discuss like this!!

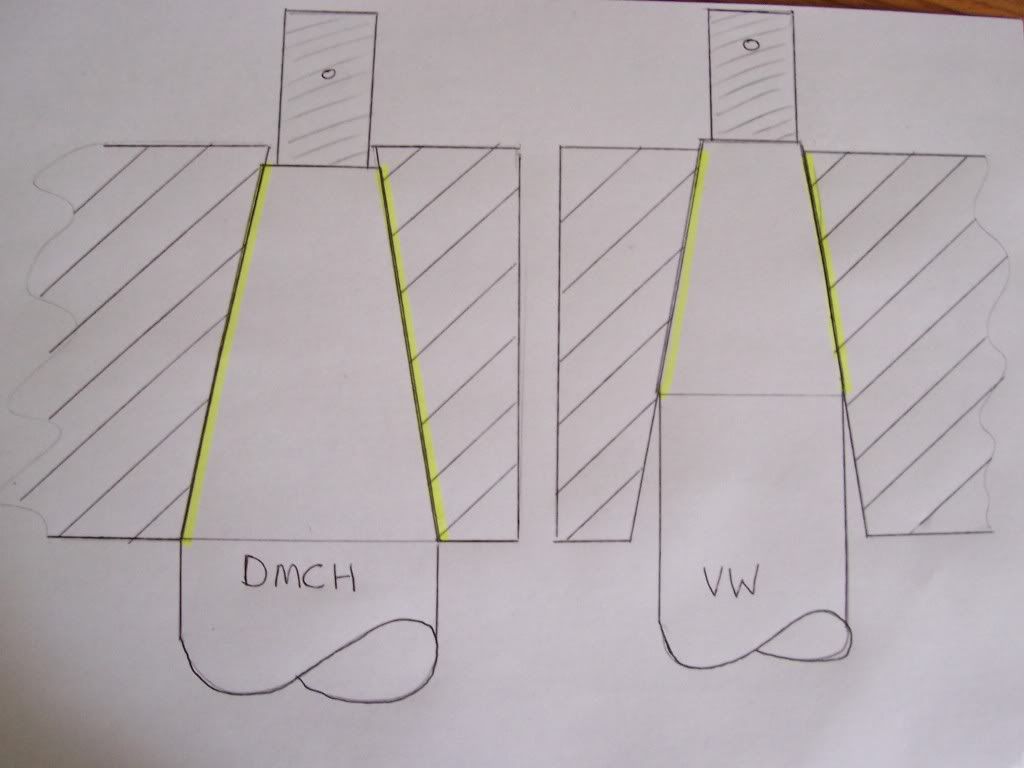

Kerr Ching ! (penny drop)

You've got it Phil....That was a difficult point I was trying to explain. The tapers ARE the same angle, but far less contact is made on the VW joint with the hub, most of this is at the top under the nut. At the lower part of the taper near the ball there is no contact in the hub. (because the shaft is parallel which makes it a smaller diameter in relation to the taper hole in the hub at the bottom) This could allow the shaft to bend around closest to the point of stress within the hub. This could cause failure too.

Back to the circlip grove.....Yes under normal conditions the suspension is holding the joint in the arm and the circlip is not required. BUT everytime you go over a bump, vibrations/force will be put on this (albeit small) it could loosen the connection of the joint in the lower arm. After all you wouldn't want to fit the joint without that circlip.

@classiccarguru1

- Darren C

- Posts: 1162

- Joined: Wed Jul 22, 2009 8:55 pm

- Location: In the garage, Emsworth. Hants

- VIN #: 4532

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

I found another reason for them to fail:

Rob van der Veer

-

RobvdVeer - Posts: 4626

- Joined: Mon Aug 17, 2009 6:34 pm

- Location: Netherlands

- VIN #: 0b111001101111

Re: DMCH Lower ball joints IS THIS WHY THEY FAIL??????

LOL Rob,

I've probably lost a few of you here, (even Phil for a while) so to try and explain without sending you to sleep.

"I was hanging a clock this morning in my bathroom, the porcelain was wet, I slipped and banged my head, when I came around I drew this....THE FACTS COMPARITOR!"

"This is what makes Special Ttravel not possible."

Ok I hope you got it now...as for the rest of you (Jez, Mec) just print it off and colour it in.

I've probably lost a few of you here, (even Phil for a while) so to try and explain without sending you to sleep.

"I was hanging a clock this morning in my bathroom, the porcelain was wet, I slipped and banged my head, when I came around I drew this....THE FACTS COMPARITOR!"

"This is what makes Special Ttravel not possible."

Ok I hope you got it now...as for the rest of you (Jez, Mec) just print it off and colour it in.

@classiccarguru1

- Darren C

- Posts: 1162

- Joined: Wed Jul 22, 2009 8:55 pm

- Location: In the garage, Emsworth. Hants

- VIN #: 4532

Return to Welcome! ... General DeLorean chat

Who is online

Users browsing this forum: No registered users and 46 guests